Polyethlene Water Pipes

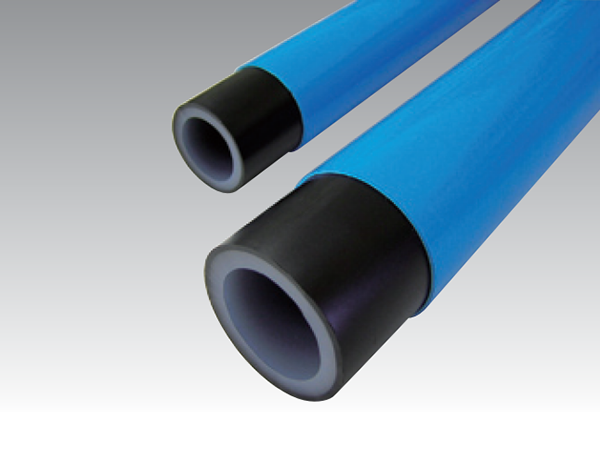

Polyethylene Solvent Penetration Prevention Coated Pipes for Water Supply

Prevents organic solvents (gasoline and kerosene) from penetrating into the pipes, ensuring safe and secure water supply pipelines.

FEATURES

Feature 1

Reduces man-hours compared to conventional solvent penetration prevention measures (sleeves and sheath pipes).

Feature 2

Scratch-proof film is provided on the outermost layer to protect the solvent penetration prevention layer, and it prevents scratches during pipe installation.

Feature 3

Since the scratch prevention layer, solvent penetration prevention layer, and pipe body are non-adhered, they can be easily peeled off using a dedicated skin cutter. Conventional joints can be used because of the non-adhesive nature of the joints.

Feature 4

Metal fittings for polyethylene double-layer pipes for water supply (Class 1) can be used.

Important points to note

Be sure to attach a cap to the end of the pipe to prevent deterioration of the material if the end of the pipe is exposed to direct sunlight. In the unlikely event that the terminal cap is removed, please cut off about 10 cm of the pipe end for safety.

SERIES PRODUCTS

RELATED PRODUCTS

EF joints for water supply (joints for polyethylene double-layer pipes for water supply)

Flexible polyethylene pipes for water supply Class 1 and EF joints enable construction of integrated pipelines with excellent seismic resistance

Epidermal Cutter

It does not scratch the surface of polyethylene pipe, which is the inner tube.

NPJX Fittings

Seismic performance-enhanced joints with a wide variety of variations.

JPW Poly Joint

Seismic performance-enhanced joints with a wide variety of variations.

OP Poly Joint

One-touch coupling with reinforced seismic performance, in-core fixes the inner surface of the pipe and prevents shrinkage even if the pipe is pulled.